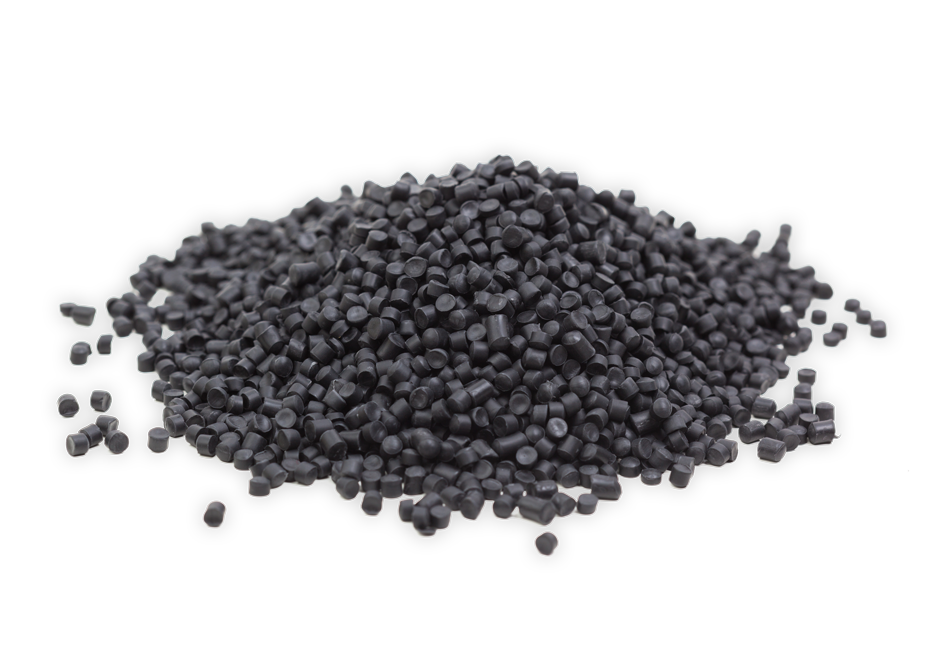

CTC manufactures 99% recycled resin created to meet the individual specifications of your business.

Each of our resins are customized per batch depending on compound needs. Our in-house, state-of-the-art facilities allow us to partner with you to customize formulas to your requirements– enhancing strength, durability, or flexibility.

General Purpose Polypropylene

Our X-Pro resins are widely used in a variety of processes using either recycled or virgin resins, providing a reliable and cost effective source for your polypropylene applications.

Automotive Certified Resin

Our expertise in automotive-grade resins is why we are the leading supplier of wheel liner resins in North America.

Custom Resin

Using fillers, modifiers and additives, our state-of-the-art lab can produce resins to fit your specific needs.

Why Choose CTC As Your Resin Supplier?

01

Lower Cost

Since our resins are recycled, they provide a lower cost and more sustainable option to virgin resins.

02

Custom Options

Our state-of-the-art facilities are capable of producing custom resins to fit your needs.

03

Reduced Oil Dependency

Utilizing recycled resins reduces dependency on foreign oils by over 10 million gallons per year.

04

High Quality

Our 99% recycled resins maintain the same, high quality of virgin resins for a fraction of the price.

A New Level of Quality

Our in-house laboratory tests all combinations of resins and recycled materials to determine the best blend for client requirements with optimal, cost-effective execution. Our state-of-the-art lab has the ability to test for:

- Material content

- Tensile strength

- Flex strength

- Izod

- Gardner impact

- Melt flow rate

- Ash content

- Density

- Shrink rate

- Moisture percentage

These all play an essential role in the performance and quality of your plastic products.